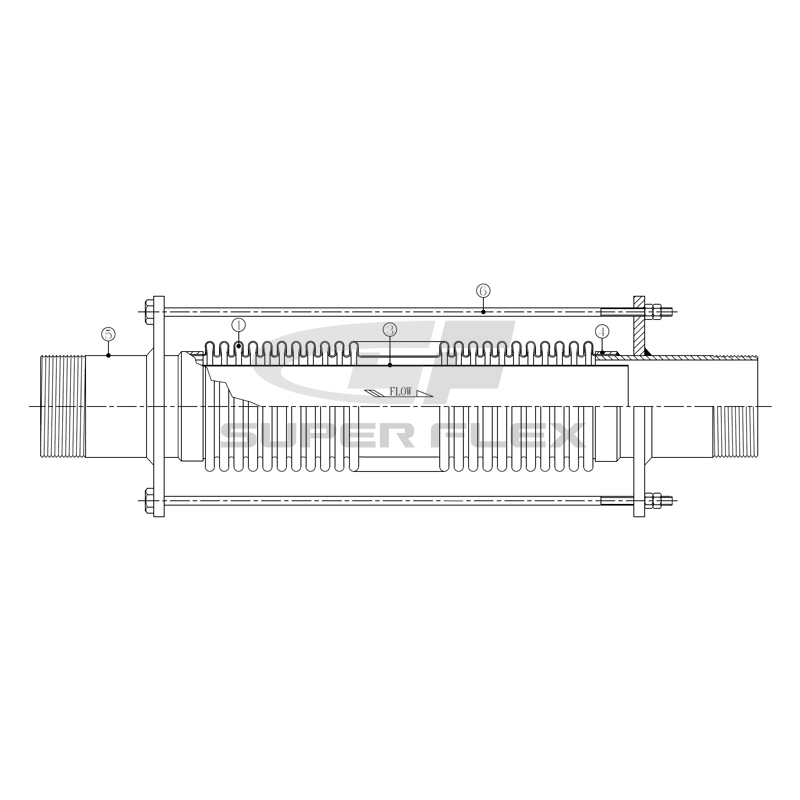

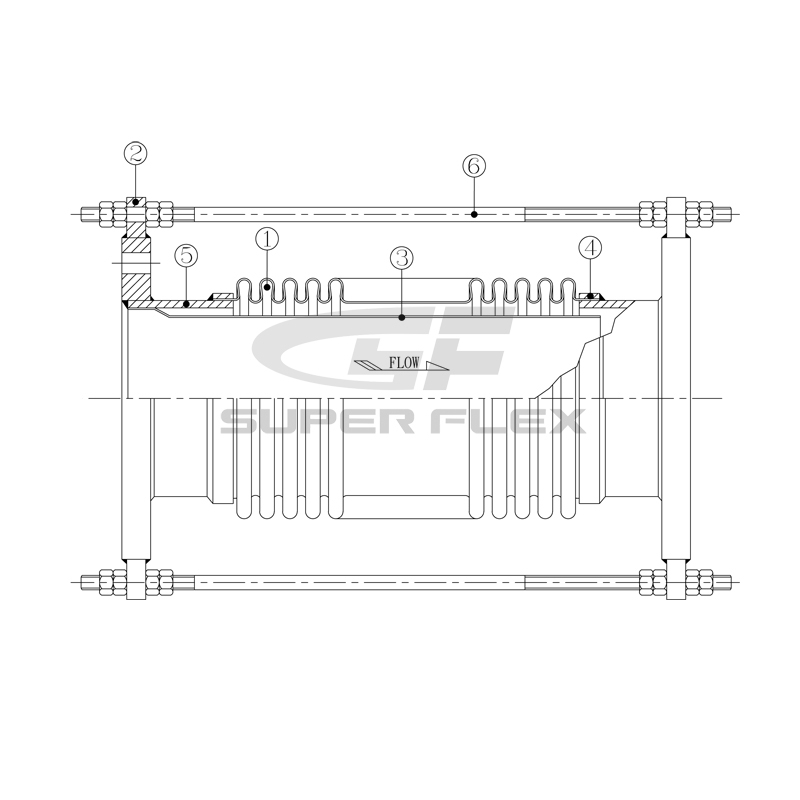

Expansion Joint SF-400STG & SF-400SG

Product Specification

SF-400STG 性能規格表 Specification

(下述工作壓力以常溫25℃為基準)

| Nominal Bore | Total Length | Bellows | Axial Movement | Tie Rods | Working Pressure | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 口徑 | 總長度 | 外徑 | 鋼板層數 | 有效面積 | 伸縮量 | 拉桿數 | 工作壓力 | |||

| mm | Ins | mm | O.D. | PLY | c㎡ | mm | mm | PCS | PSI | Kg/c㎡ |

| 20 | 3/4 | 300 | 34 | 2 | 7.1 | +5 | -25 | 2 | 300 | 20 |

| 25 | 1 | 300 | 39 | 2 | 9.1 | +5 | -25 | 2 | 300 | 20 |

| 32 | 1-1/4 | 400 | 50 | 2 | 16 | +10 | -40 | 2 | 300 | 20 |

| 40 | 1-1/2 | 400 | 57 | 2 | 19.7 | +10 | -40 | 2 | 300 | 20 |

| 50 | 2 | 400 | 74 | 2 | 34 | +10 | -40 | 2 | 300 | 20 |

| 65 | 2-1/2 | 400 | 90 | 2 | 51.3 | +10 | -40 | 2 | 300 | 20 |

SF-400SG 性能規格表 Specification

(口徑26"以上規格另行提供,下述工作壓力以常溫25℃為基準)

| Nominal Bore | Total Length | Bellows | Axial Movement | Tie Rods | Working Pressure | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| 口徑 | 總長度 | 外徑 | 鋼板層數 | 有效面積 | 伸縮量 | 拉桿數 | 工作壓力 | |||

| mm | Ins | mm | O.D. | PLY | c㎡ | mm | mm | PCS | PSI | Kg/c㎡ |

| 20 | 3/4 | 250 | 34 | 2 | 7.1 | +5 | -25 | 2 | 300 | 20 |

| 25 | 1 | 250 | 39 | 2 | 9.1 | +5 | -25 | 2 | 300 | 20 |

| 32 | 1-1/4 | 350 | 50 | 2 | 16 | +10 | -40 | 2 | 300 | 20 |

| 40 | 1-1/2 | 350 | 57 | 2 | 19.7 | +10 | -40 | 3 | 300 | 20 |

| 50 | 2 | 350 | 74 | 2 | 34 | +10 | -40 | 3 | 300 | 20 |

| 65 | 2-1/2 | 350 | 90 | 2 | 51.3 | +10 | -40 | 4 | 300 | 20 |

| 80 | 3 | 350 | 104 | 2 | 69.1 | +10 | -40 | 4 | 300 | 20 |

| 100 | 4 | 350 | 130 | 2 | 112.2 | +10 | -40 | 4 | 300 | 20 |

| 125 | 5 | 350 | 161 | 2 | 174.4 | +10 | -40 | 4 | 300 | 20 |

| 150 | 6 | 350 | 187 | 2 | 237.8 | +10 | -40 | 4 | 300 | 20 |

| 200 | 8 | 350 | 247 | 3 | 432.3 | +10 | -40 | 4 | 300 | 20 |

| 250 | 10 | 350 | 309 | 3 | 667.8 | +10 | -40 | 4 | 300 | 20 |

| 300 | 12 | 350 | 359 | 3 | 921.9 | +10 | -40 | 4 | 300 | 20 |

| 350 | 14 | 350 | 393 | 3 | 1108 | +10 | -40 | 4 | 300 | 20 |

| 400 | 16 | 350 | 448 | 3 | 1442 | +10 | -40 | 4 | 300 | 20 |

| 450 | 18 | 350 | 501 | 3 | 1814 | +10 | -40 | 4 | 300 | 20 |

| 500 | 20 | 350 | 553 | 3 | 2219 | +10 | -40 | 4 | 300 | 20 |

| 600 | 24 | 350 | 663 | 3 | 3015 | +10 | -40 | 4 | 300 | 20 |

.jpg)