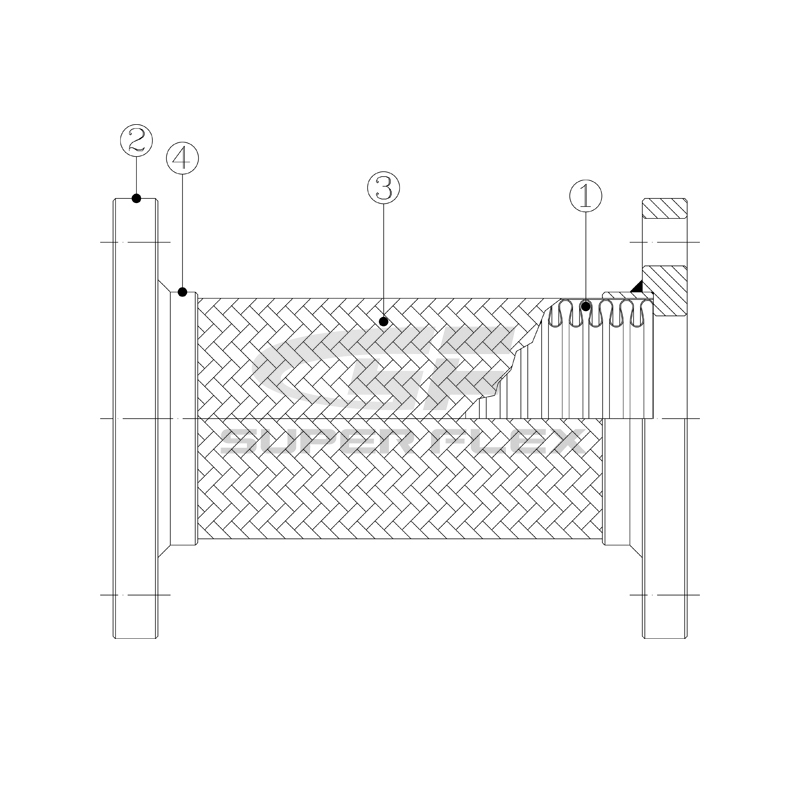

Flexible Joint SF-600 / SF-600H

Product Specification

SF-600 性能規格表 Specification

(口徑14"以上規格另行提供,下述工作壓力以常溫25℃為基準)

| Nominal Bore | Total Length | Bellows | Lateral Movement | Working Pressure | ||||

|---|---|---|---|---|---|---|---|---|

| 口徑 | 總長度 | 外徑 | 板厚 | 容許變位量mm | 工作壓力 | |||

| mm | Ins | mm | O.D. | T | PSI | Kg/c㎡ | ||

| 15 | 1/2 | 200 | 18 | 0.25 | 40 | 26 | 300 | 20 |

| 20 | 3/4 | 200 | 26 | 0.25 | 40 | 26 | 300 | 20 |

| 25 | 1 | 200 | 33 | 0.25 | 38 | 24 | 300 | 20 |

| 32 | 1-1/4 | 200 | 41 | 0.25 | 36 | 21 | 300 | 20 |

| 40 | 1-1/2 | 200 | 52 | 0.3 | 33 | 16 | 300 | 20 |

| 50 | 2 | 230 | 70 | 0.3 | 28 | 15 | 300 | 20 |

| 65 | 2-1/2 | 230 | 85 | 0.4 | 24 | 13 | 240 | 16 |

| 80 | 3 | 230 | 96 | 0.4 | 20 | 11 | 240 | 16 |

| 100 | 4 | 230 | 125 | 0.4 | 18 | 9 | 195 | 13 |

| 125 | 5 | 280 | 153 | 0.5 | 23 | 14 | 150 | 10 |

| 150 | 6 | 280 | 175 | 0.5 | 20 | 12 | 150 | 10 |

| 200 | 8 | 300 | 231 | 0.6 | 20 | 8 | 150 | 10 |

| 250 | 10 | 330 | 288 | 0.6 | 17 | 8 | 150 | 10 |

| 300 | 12 | 350 | 339 | 0.8 | 15 | 7 | 150 | 10 |

SF-600H 性能規格表 Specification

(口徑14"以上規格另行提供,下述工作壓力以常溫25℃為基準)

| Nominal Bore | Total Length | Bellows | Lateral Movement | Working Pressure | ||||

|---|---|---|---|---|---|---|---|---|

| 口徑 | 總長度 | 外徑 | 板厚 | 容許變位量mm | 工作壓力 | |||

| mm | Ins | mm | O.D. | T | PSI | Kg/c㎡ | ||

| 15 | 1/2 | 200 | 18 | 0.25 | 40 | 26 | 300 | 20 |

| 20 | 3/4 | 200 | 26 | 0.25 | 40 | 26 | 300 | 20 |

| 25 | 1 | 200 | 33 | 0.25 | 38 | 24 | 300 | 20 |

| 32 | 1-1/4 | 200 | 41 | 0.25 | 36 | 21 | 300 | 20 |

| 40 | 1-1/2 | 200 | 52 | 0.3 | 33 | 16 | 300 | 20 |

| 50 | 2 | 230 | 70 | 0.3 | 28 | 15 | 300 | 20 |

| 65 | 2-1/2 | 230 | 85 | 0.4 | 24 | 13 | 300 | 20 |

| 80 | 3 | 230 | 96 | 0.4 | 20 | 11 | 300 | 20 |

| 100 | 4 | 230 | 125 | 0.4 | 18 | 9 | 300 | 20 |

| 125 | 5 | 280 | 153 | 0.5 | 23 | 14 | 300 | 20 |

| 150 | 6 | 280 | 175 | 0.5 | 20 | 12 | 300 | 20 |

| 200 | 8 | 300 | 231 | 0.6 | 20 | 8 | 300 | 20 |

| 250 | 10 | 330 | 288 | 0.6 | 17 | 8 | 300 | 20 |

| 300 | 12 | 350 | 339 | 0.8 | 15 | 7 | 300 | 20 |

.jpg)